Genuine Dark Pine Tar

Description

Genuine Dark Pine Tar is the mother of all the pine tar products. It is produced by slowly burning the resin from the root stock of pine trees, giving it a distinctive, pleasant smoky smell. Pine tar has been used in Scandinavia for over 1000 years to protect and preserve wooden buildings, boats, jetties and everyday items against rot. Natural tar is also mildly antiseptic and even has a long history in veterinary, medical, and personal care applications.

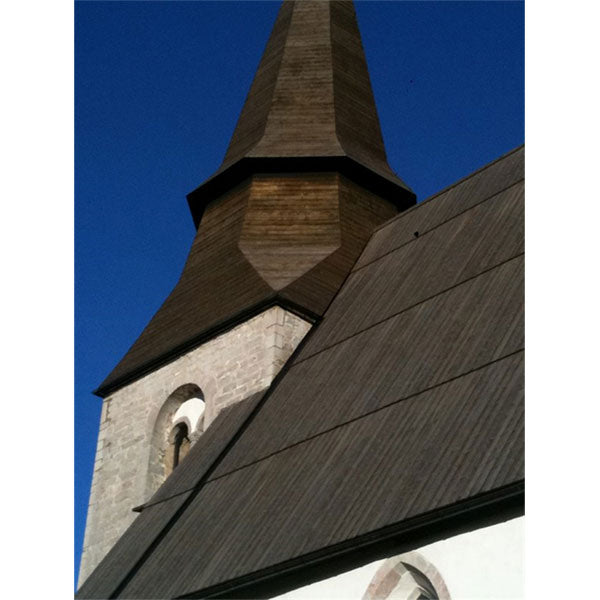

Genuine Pine Tar is used for the preservation of wood outdoors such as cottages, splint roofs, boats, bridges, and more. It is also recommended for the treatment of wooden church roofs and other cultural buildings made of wood. The Pine Tar can also be used on animal hooves and other veterinary applications. It can also be used for making soap and personal care products.

This original form of pine tar is sometimes also called Stockholm Tar, as it was the largest export product from Sweden by the end of the 18th Century and through the 19th Century, and it was an essential material to many industries, including naval and merchant shipping concerns all over the world.

Genuine Pine Tar has a dark colour from the ultra-fine carbon particulate of the burning process, and it contains all the elements of rosin and fatty acids and their conversion products such as rosin oil, oxidized acids, esters, high-boiling terpenes, and fatty alcohols, which characterizes a pine tar of high quality and excellent protection according to traditional knowledge.

Colour

Genuine Dark Pine Tar is a natural material that does not contain any pigment or chemical UV inhibitors, and it is not a film-building material. It has no UV protection against the sun's UV rays, and the surface will, therefore, turn grey over time. Over time and with subsequent applications, the colour tone of the surface will turn from warm amber tones to a darker, aged, grey-brown patina as it is exposed to UV light and to the elements. In high UV exposure and on horizontal surfaces, this greying process is faster than on surfaces that are more protected from the sun and the elements. The pigment in our coloured pine tars can offer more UV protection.

Testing

Use the Pine Tar Test Kit to help with learning the nuances of the material for staining and protecting surfaces and to ensure you achieve the desired result. Test how the material will look on your particular surface, and test application methods and strategies for your particular project.

Application

Clean the surface with Linseed Soap and water to remove dust and dirt from the wood with a brush. Rinse well and allow to dry.

Apply Pine Tar to an absorbent surface, such as bare wood or wood that was formerly treated with Pine Tar, distemper, or natural oil, such as Purified Linseed Oil. Pine Tar is best applied with a brush, so you can work the material into the wood. It is possible to spray Pine Tar after it has been warmed or diluted.

Pine Tar is a penetrating material that is not meant to build a thick film on the surface, or there is a risk of cracking over time and possibly even bleeding back out of the wood during hot weather.

Pine Tar comes concentrated and can be applied on its own or diluted. There are many old recipes. For most applications on absorbent wood, we like to mix 50/50 with Purified Linseed Oil and apply the mixture warm (approx. 60ºC / 140ºF) and to a warm surface in order to avoid the need for solvents. This helps to promote penetration into the wood for best protection. Adjust the ratio according to your project. See the Auson Technical Data Sheet below for more detail.

Another popular old recipe is for "boat soup", or Roslagsmahogny in Sweden, which is a mixture of equal parts of Pine Tar, Linseed Oil, and Turpentine.

The approximate spread rate of this pine tar mixture is 60-100 sqft per litre, depending on the mixing ratio, density, smoothness, and overall condition of the substrate. It is also important to consider the environmental conditions. See the Auson Technical Data Sheet below for more detail.

Minimum operating temperature: 10-15ºC on the surface and in the air. Beware of invisible condensation on surfaces below 15ºC.

Drying can take from several days to several weeks depending on the weather and other environmental conditions as well as on the condition of the surface and its porosity.

Notes

Genuine Pine Tar is a product of nature that is viscous and sticky, where the viscosity may range slightly from batch to batch.

Raw Linseed Oil is a deep penetrating oil that is slow to dry. It must be well absorbed by the timber and is well suited to most projects, including wooden facades and roofs.

Boiled Linseed Oil is a drying oil that can become hard and form a film on the surface after several coats and is well suited to projects where a faster drying time and harder finish is desired, such as walked-on surfaces.

Tip

Achieve a surface with a rich, dark, aged patina right away by pretreating with a reactive wood stain such as LifeTime Wood Treatment, and then proceed to apply Genuine Dark Pine Tar and Linseed Oil for long-lasting and nourishing protection.

Documents