Preserve Wood, Naturally

Ancient wood preservation, still used today.

Puts the protective resins back into the wood that the tree itself uses against attacks from mould, fungus, and rot.

For marine, architectural, wooden roofs, bridges, jetties, decks, barns, fences, garden, veterinary, personal care, and more.

Feel good about using wood again!

The first recorded use of wood tar by ancient Mesopotamians was over 7000 years ago. Since then, the ancient Greeks, the Vikings, European naval empires, and common people through today have found endless uses for the protective qualities of wood tar.

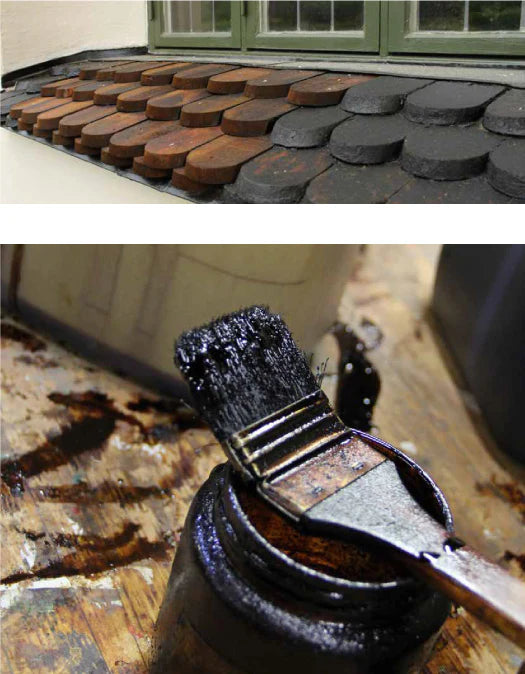

Pine tar has been used extensively in boat and ship construction on wooden hulls and decks, ropes, oakum fibre, rigging, and more. It has been used on buildings to preserve wooden elements such as logs, facades, roofs, decks, fences, and even below grade.

Over time it has even been used to protect many other things from leather to baseball bats to fishing gear to gun stocks to cart axles to animal hooves, and more.

Pine tar, or Stockholm Tar, was Sweden's largest export from 1648 to the early 20th Century and was known to be of the highest quality.

Pine Tar is literally a material from the forest, making it environmentally safe to use under the strictest circumstances.

It is an ideal wood preservative for garden boxes and even on organic farms, where strict regulations prevent the use of harmful chemicals. Plus, with its mild antiseptic properties, pine tar is even used in a variety of pharmaceutical, veterinary, and personal care products.

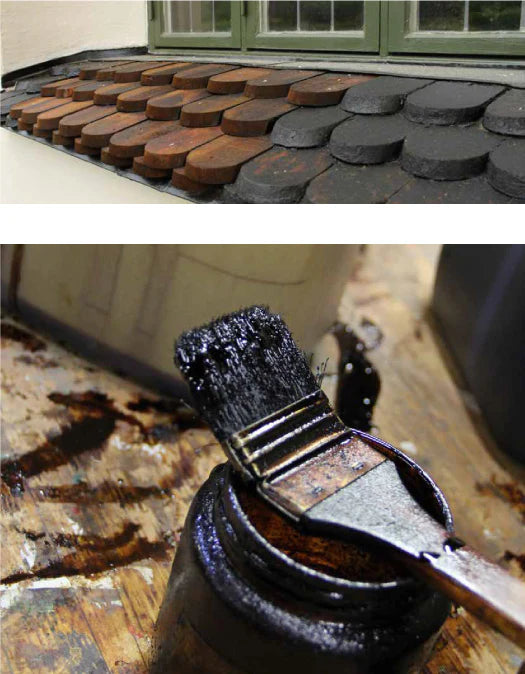

There are many ways to mix and use pine tar depending on the project and the desired result. Use it concentrated out of the can warmed up. Use it thinned with linseed oil or with a combination of linseed oil and high quality solvent.

We favour mixing 50/50 with Purified Linseed Oil, and no solvents are necessary. Adjust the ratio according to your project. Apply warm if possible and onto a warm surface for better penetration and longer-term results. Use a stiff bristle brush as large as possible to massage the pine tar mixture into the wood and to cover a large area at a time. Apply at least 2 coats.

The average spread rate of our pine tar mixture above or of the premixed Grey Pine Tar Vitriol is 60-100 sqft per litre, depending on the condition of the substrate.

Maintain with more coats as the surface begins to look dry and faded. Over time, the maintenance interval will get longer and longer. Historically, well treated wood was maintained approximately every decade. The pleasant, smoky smell of pine tar diminishes with time, making it ideal for use outdoors.

The first recorded use of wood tar by ancient Mesopotamians was over 7000 years ago. Since then, the ancient Greeks, the Vikings, European naval empires, and common people through today have found endless uses for the protective qualities of wood tar.

Pine tar has been used extensively in boat and ship construction on wooden hulls and decks, ropes, oakum fibre, rigging, and more. It has been used on buildings to preserve wooden elements such as logs, facades, roofs, decks, fences, and even below grade.

Over time it has even been used to protect many other things from leather to baseball bats to fishing gear to gun stocks to cart axles to animal hooves, and more.

Pine tar, or Stockholm Tar, was Sweden's largest export from 1648 to the early 20th Century and was known to be of the highest quality.

Pine Tar is literally a material from the forest, making it environmentally safe to use under the strictest circumstances.

It is an ideal wood preservative for garden boxes and even on organic farms, where strict regulations prevent the use of harmful chemicals. Plus, with its mild antiseptic properties, pine tar is even used in a variety of pharmaceutical, veterinary, and personal care products.

There are many ways to mix and use pine tar depending on the project and the desired result. Use it concentrated out of the can warmed up. Use it thinned with linseed oil or with a combination of linseed oil and high quality solvent.

We favour mixing 50/50 with Purified Linseed Oil, and no solvents are necessary. Adjust the ratio according to your project. Apply warm if possible and onto a warm surface for better penetration and longer-term results. Use a stiff bristle brush as large as possible to massage the pine tar mixture into the wood and to cover a large area at a time. Apply at least 2 coats.

The average spread rate of our pine tar mixture above or of the premixed Grey Pine Tar Vitriol is 60-100 sqft per litre, depending on the condition of the substrate.

Maintain with more coats as the surface begins to look dry and faded. Over time, the maintenance interval will get longer and longer. Historically, well treated wood was maintained approximately every decade. The pleasant, smoky smell of pine tar diminishes with time, making it ideal for use outdoors.

Documents

Pine Tar: Nature's Own Wood Protection [EN]

Goudron de pin: la protection naturelle du bois [FR]

Pine Tar Painting Guide [EN]

Minimum operating temperature should be 10-15ºC on the surface and in the air. Beware of invisible condensation on surfaces below 15ºC.

Drying can take from 24 hours to several days to several weeks depending on the weather and other environmental conditions as well as on the condition of the surface and its porosity.

Nature's Own Wood Paint - Pine Tar by Auson

Paint with Red Pine Tar - Auson Pigmented Pine Tars