Special Kiln Burned Pine Tar

Description

Special Kiln Burned Pine Tar is a pure, natural product with a golden colour, a low content of pitch, a high content of resin, and a high degree of purity. Kiln Burned Pine Tar is produced in small batches, and because of its purity and its antiseptic properties, it is especially sought after for veterinary use, for personal care products, and also for wood preservation.

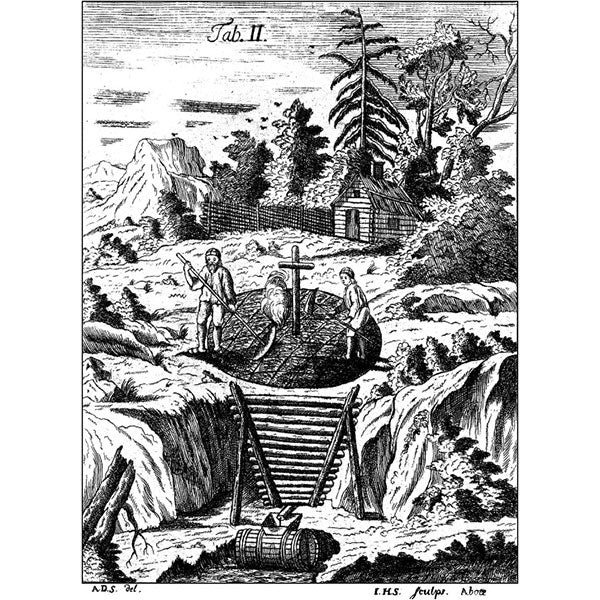

Special Kiln Burned Pine Tar is produced according to traditional methods in special outdoor burning pits or "dales". Resinous pine wood is carefully chosen, prepared, and laid out in the dale, and it is then covered in earth so that it burns very slowly, resulting in a very pure form of pine tar with a low amount of carbon. This has become a ceremony that is still practiced annually in Gotland, Sweden, certain parts of Norway, and in Finland.

Veterinary

In veterinary use, it's used as an antiseptic and hoof care treatment for horses and cattle. It also has been used when chickens start pecking the low hen. Applying a smear of pine tar on the wound acts as a natural germicidal/antibacterial and discourages continued attacks on the affected hen due to its foreign texture.

Personal care

In personal care products, such as shampoos and soaps, Special Kiln Burned Pine Tar is added for its unique but pleasant resinous odour and also for its mild antiseptic qualities.

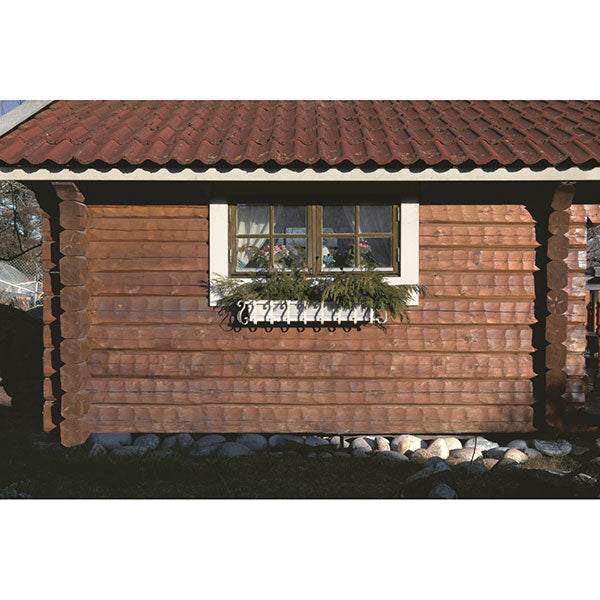

Wood preservation

On buildings, this pure pine tar with a low content of pitch offers a more golden amber tone in the initial application. It can be possible to maintain these warm wood tones, but it requires very proactive cleaning and maintenance. See notes on colour below.

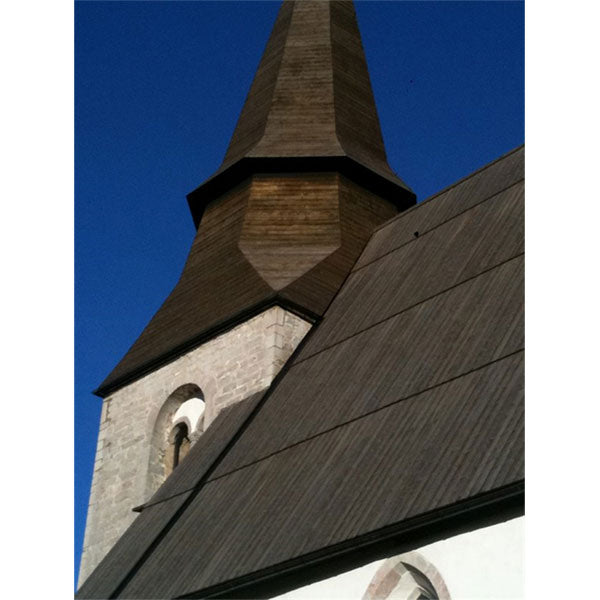

Colour

Pine Tar is a natural material and does not contain any chemical UV inhibitors. Over time and with subsequent applications, the colour tone of the surface will turn from warm golden amber tones to a darker, aged, grey-brown patina as it is exposed to UV light and to the elements. In high UV exposure and on horizontal surfaces, this greying process is faster than on surfaces that are more protected form the sun and the elements. The pigment in our coloured pine tars can offer more UV protection if desired.

Application

Apply Pine Tar to bare wood or to wood that was formerly treated with Pine Tar or natural oil, such as Purified Linseed Oil

Clean the surface with Linseed Soap and water to remove dust and dirt from the wood with a brush. Rinse well and allow to dry.

Pine Tar comes concentrated and can be applied on its own or diluted. There are many old recipes. For most applications on wood, we like to mix 50/50 with Purified Linseed Oil and applying the mixture warm (approx. 60ºC) and to a warm surface in order to avoid the need for solvents. This helps to promote penetration into the wood for a long-lasting result. Adjust the ratio according to your project. See the Auson Technical Data Sheet below for more detail.

The approximate spread rate of this pine tar mixture is 60-100 sqft per litre, depending on the mixing ratio, density, smoothness, and overall condition of the substrate. It is also important to consider the environmental conditions. See the Auson Technical Data Sheet below for more detail.

Minimum operating temperature: 10 - 15ºC on the surface and in the air. Beware of invisible condensation on surfaces below 15ºC.

Drying can take from several days to several weeks depending on the weather and other environmental conditions as well as on the condition of the surface and its porosity.

Note

Special Kiln Burned Pine Tar is a product of nature that is viscous and sticky, where the viscosity may range slightly from batch to batch.

Raw Linseed Oil is a deep penetrating oil that is slow to dry. It must be well absorbed by the timber and is well suited to most projects, including wooden facades and roofs.

Boiled Linseed Oil is a drying oil that can become hard and form a film on the surface after several coats and is well suited to projects where a faster drying time and harder finish is desired, such as walked-on surfaces.

Documents

TDS Special Kiln Burned Pine Tar

SDS Special Kiln Burned Pine Tar